Tantalum powder is a form of the rare and highly sought-after metal tantalum, which is used in a variety of industrial and medical applications. Tantalum powder is produced by the reduction of tantalum ore, which is composed of tantalum oxide, Ta2O5. The powder is often used in the production of alloys and other metallic components, and is also used in medical implants and prosthetics due to its high corrosion resistance, biocompatibility, and strength.

Tantalum powder is produced through the reduction of tantalum oxide using a process known as chemical vapor deposition (CVD). In this process, the oxide is subjected to a high-temperature environment, usually between 1200 and 1800 degrees Celsius, in the presence of a reducing gas. This process combines the oxide with the reducing gas to create the elemental tantalum in powder form.

The high melting point of tantalum and its corrosion resistance make it an ideal material for many industrial and medical applications. In industrial settings, tantalum powder is often used to create alloys that are resistant to corrosion and heat. It is also used to create strong but lightweight metal components, such as compressor blades and turbine blades, as well as high-grade electrical components. In the medical field, tantalum powder is used to create implants and prosthetics due to its non-toxic, biocompatible, and corrosion-resistant properties.

Tantalum powder is a highly valuable material due to its unique properties and is used in a variety of applications. Its high melting point, corrosion resistance, and biocompatibility make it an ideal material for medical implants and prosthetics, as well as a wide range of industrial and commercial applications. The powder is created through the reduction of tantalum oxide using a process known as chemical vapor deposition and is highly sought-after due to its unique properties and applications.

Tantalum (Tantalum, Ta) has an atomic number of 73,180.95, a pale gray, hard texture, and a hardness of 6-6.5 Mohs, after diamond, with a density of 16.68g/cm3 and a melting point of 2996℃.

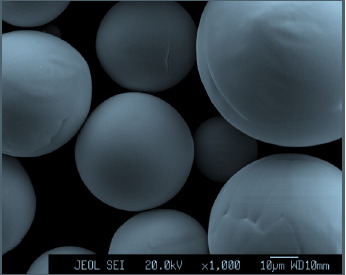

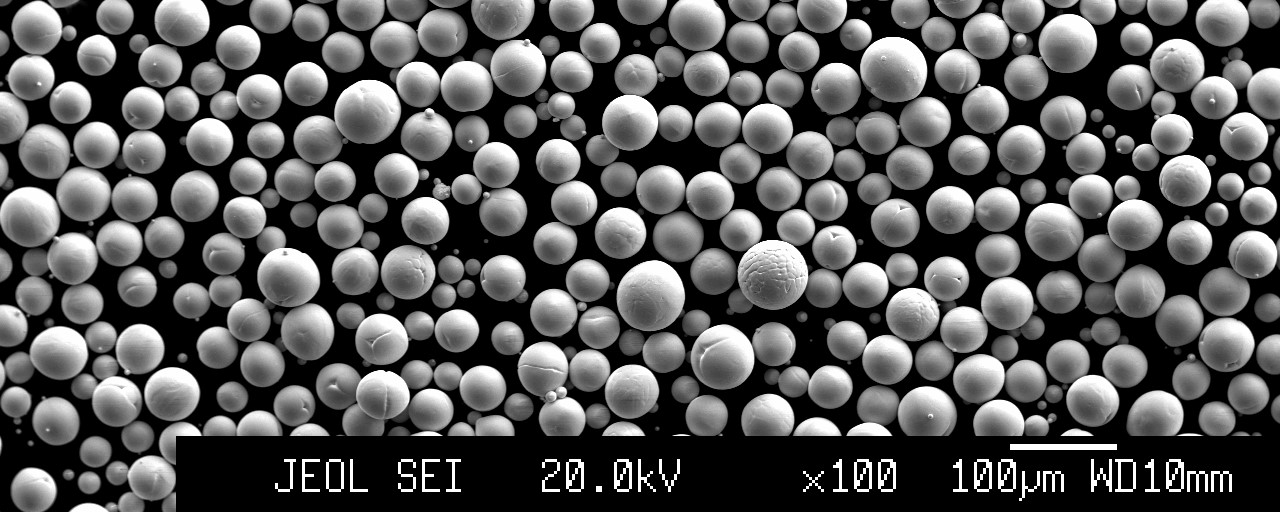

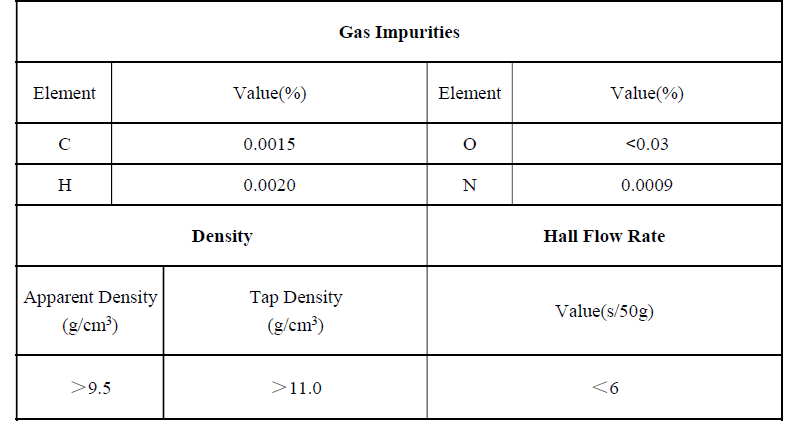

Medical implants are an important application direction for 3D printing. Spherical tantalum powder specifically supplied by Heeger Materials Inc has been put into mass production. This product has advantages in both particle size and liquidity, with the lowest oxygen content, which can well meet the requirements of metal 3D printing.

This tantalum powder has a very high loose loading density of 9.84 g/cm3, close to 60% of the density of tantalum blocks. At the same time, this powder has excellent liquidity, and it feels like water and flows very smoothly. On the other hand, in the particle size range of ultrafine powder, the physical characteristics of high spherical make the powder have better dispersion and larger specific surface area, making the powder more stable and excellent.

The conventional products of this tantalum powder are 60-100nm (nano grade), 500-4000nm (sub-micron grade), 5-15um (ultra-fine powder), 15-45um (micron grade 3D printed powder), and also can customize other sizes for customers. We solve the problem of refractory tungsten molybdenum tantalum, considering both sphericity and ultrafine particle size. We have accumulated a lot of application experience, can help customers effectively put into use, for example, using EOS equipment we recommend using 240W laser power, scanning speed can choose 600-700.