Contents

Chapter I: An Introduction to PCB Turnkey Service

Chapter 2: What to look at when looking for a PCB Turnkey Service?

- Quality of Boards

- Manufacturer’s Technological Capabilities

- Cost

- Lead and Delivery Times

Chapter 3: Why Does One Need a PCB Turnkey Service?

- What is a Prototype Board?

- Turnkey and Production Boards

- Turnkey PCB Fabrication

- Turnkey PCB Assembly

Chapter 4: Final Steps before Finalizing on a PCB Turnkey Service

- Do a Sample Check

- Test Their Feedback

- Shipping Methods, Times and Costs

Chapter 5 What WellPCB Can Offer

- Rapid Prototype Service

- Quick Online Quotation System

- Cash on Delivery Service

- Superior Materials

- Low Cost and Promotional Offers

Chapter 6: Conclusion

Chapter 1: An Introduction to PCB Turnkey Service

For anyone who’s into electronics, whether it be an Individual or a big company, there always comes the point when one has to get a PCB fabricated and so must choose a PCB Turnkey Service.

There are several manufacturers to choose from, and it’s quite often not an easy task to do so. Different manufacturers have different methods and features when it comes to getting PCBs made.

The term turnkey on PCB refers to a board that can be placed in the final product and delivered immediately.

Luckily we will walk you through the entire process of what to look at when deciding on a PCB Turnkey Service.

Chapter 2: What to look at when looking for a PCB Turnkey Service?

As a general rule of thumb, the following are the most important factors when looking for a PCB Turnkey Service

2.1 Quality of Boards

One of the most important factors to consider is always quality; every individual or company would certainly always want the highest quality of boards going into their products.

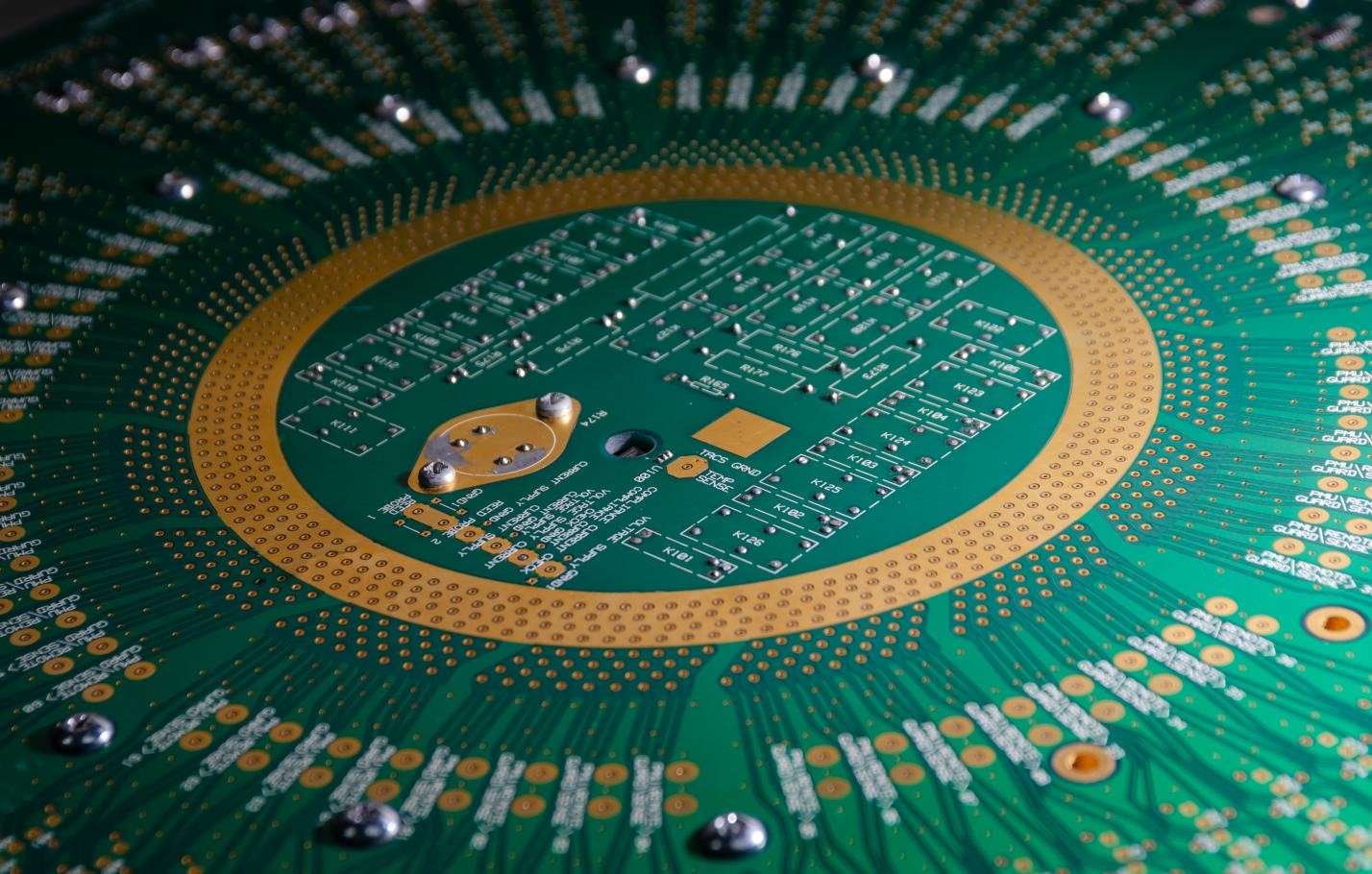

Generally speaking, a high-quality board would have tight tolerances on crucial things. These include trace width and spacing, the position and size of all drilled holes and vias along with an accurate trace copper thickness.

High-quality boards will also have a very accurate layer stack-up, which is especially useful when your design contains features like impedance controlled traces.

2.2 Manufacturer’s Technological Capabilities

The other important factor when choosing a PCB turnkey service is always the fact that whether your board manufacturer can manufacture your design requirements.

Some composite boards may have multiple layers. Sometimes up to 24 Layers and above. Other boards may be extremely small and have very thin traces and clearance constraints. Not all manufacturers can handle such specifications.

Even a high current board that requires a high copper thickness would need to be sent out to a PCB Turnkey service that can make your board with higher than standard copper thicknesses.

2.3 Cost

Cost is always a governing factor; the cost of the PCB sometimes is a major contributor to the cost of your finished product.

To make sure your product has a sufficient profit margin, a customer must choose a PCB turnkey service that offers reasonable pricing options and yet delivers good quality for the price.

Might offer many more options compared to others. A simple example here can be the choice of solder mask color, while one jhd pcb manufacturer china may only provide two colors, others may provide more than 4-5.

2.4 Lead and Delivery Times

If you are on a tight schedule, then the lead times and delivery times involved for getting a PCB made might be the most important factor to look at.

These times typically include the time taken for your design to go into production, get the board made and then to have it shipped to the customer’s doorstep.

A week or more is common for many services to get the board made. Shipping is then dependent on what options are available as per the customer’s country.Typically, manufacturers from China are faster than products offered by local companies.

Chapter 3: Why Does One Need a PCB Turnkey Service?

3.1 What is a Prototype Board?

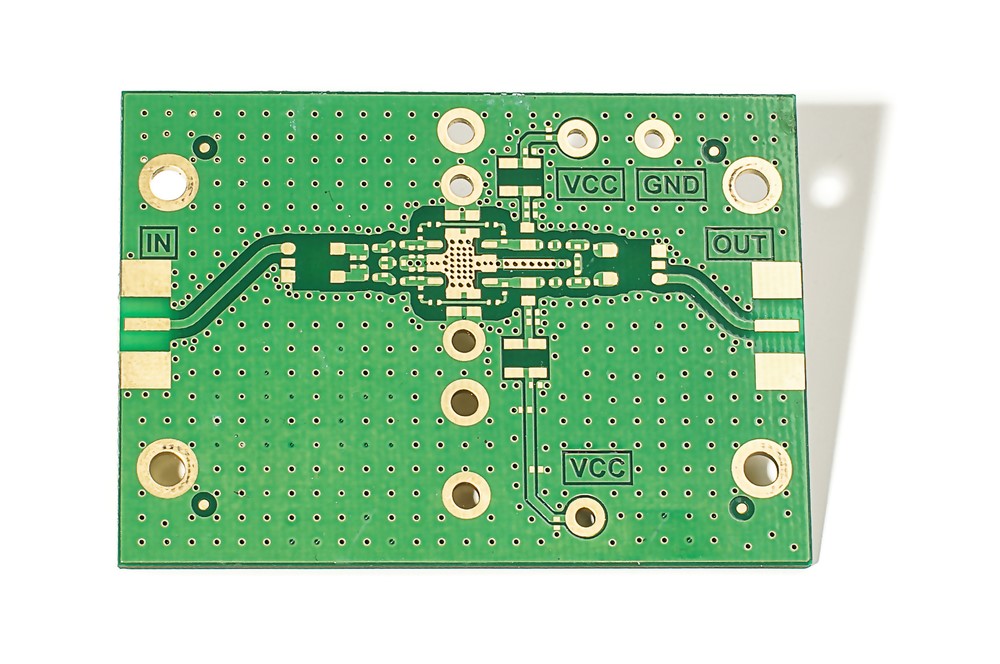

Suppose you have a new design Idea in mind, and for some reason, you don’t want to breadboard or perfboard your idea, or the circuit is complex. Then you can go for a quick prototype board that is offered by many PCB manufacturers.

A Prototype board has the following features:

1. The tolerances aren’t very precise.

2. They are only intended for quick testing purposes and to prototype designs

- They are usually much cheaper and can be made very quickly, sometimes in just 2-3 days compared to full production boards that take longer.

- Sometimes they have lower temperature grade ratings than full production boards.

- They are manufacturing a small number. Usually less than 100.

So, in conclusion, these boards are great for hobbyists who want a quick and cheap PCB and aren’t worried too much about long term effects and durability.

3.2 Turnkey and Production Boards

A full turnkey production board is usually a PCB that will go into a finished product that may be sold in large numbers. A production board is usually made in thousands of quantity and is preceded by testing and debugging a circuit on a prototype board.

Production boards have features like:

- High durability.

- The tolerances for drill size, vias, and other features are very strict.

- High-temperature ratings

- Usually manufactured in greater than a 1000 numbers.

3.3 Turnkey PCB Fabrication

Once you’ve decided on whether you want to get a prototype board or a full production board. Then you can go to your manufacturer’s website and upload your design/Gerber files and get the fabrication going.

Many PCB companies will often provide a full cost quotation while you are placing the order on their website, and this makes the process much more convenient. The cost is usually dependent on factors like the number of layers, size of the boards, copper thickness used, and many other details.

3.4 Turnkey PCB Assembly

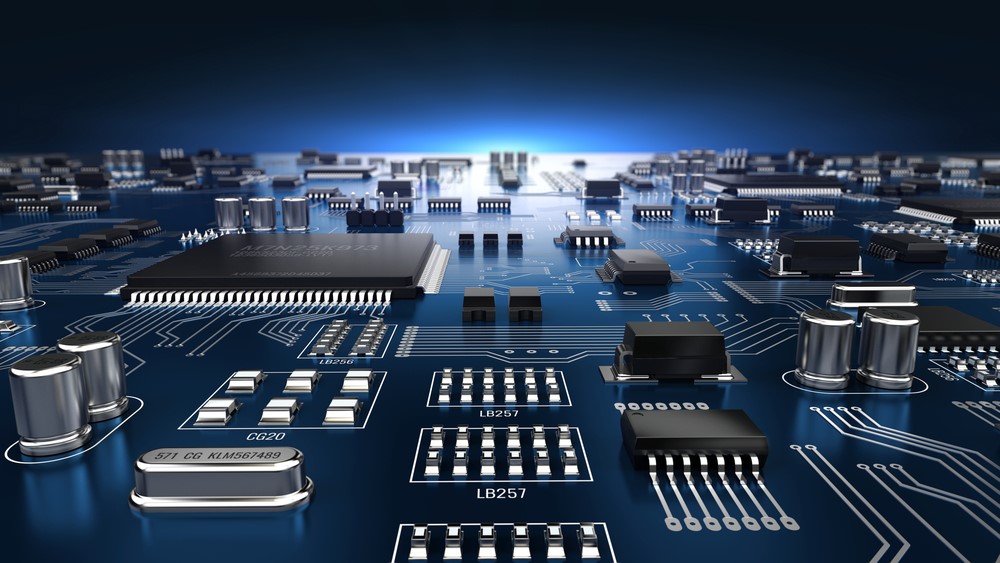

Other than just manufacturing PCBs, a full turnkey PCB service will also offer the service of PCB assembly.

PCB assembly would mean getting all components in your design soldered onto the PCB. It is a very valuable service, especially if your boards have a lot of small surface mount components, and the board needs to be mass produced in high numbers.

The assembly is usually done using high end pick and place machines and reflow ovens which a small company may not be able to afford or have the expertise to use, hence it makes a lot of sense to get PCBs assembled by a turnkey PCB assembly service.

A full overview of PCB assembly can be read here:

A demo video of the PCB assembly process can be seen here:

Chapter 4: Final Steps before Finalizing on a PCB Turnkey Service

Here are the things you need to do before completing the PCB service.

4.1 Do a Sample Check

The first thing to do would be to order a small quantity of your design and go over the quality. Look at the tolerances of the drilled holes and clearance from ground planes. Minor details like silkscreen font should also be looked at if you want a high-quality board.

4.2 Test Their Feedback

It’s a good idea to do some googling around and looking at what other people have to say about the PCB manufacturer.

Apart from the feedback section that the PCB manufacturers already have on their website. One should also look at the opinion and experiences of customers on popular electronics forums and websites like Reddit.

4.3 Shipping Methods, Times and Costs

Finally, you need to research what your PCB turnkey service is offering shipping methods. These would include standard shipping along with options for expedited shipping also.

The costs involved in the shipping process are also important, especially if you are looking at a small number of boards, where shipping costs can be a large part of the total cost.

Chapter 5 What WellPCB Can Offer

Rapid Prototype Service:

WellPCB offers a rapid prototyping service; you can order online by submitting your designs for a low cost and get your fabricated PCB in a short period.

We can produce quick turns to meet 24 hour delivery for double-sided PCBs and 48 hours for 4 to 8 layer boards.

It is also possible to complete a circuit board of up to 10 layers in 120 hours.

Quick Online Quotation System

Many times customers have to wait for a quote and don’t get an idea of the exact price tag. WellPCB offers an online quotation system, and you get to see the exact cost for your PCB.

Cash on Delivery Service

WellPCB also provides cash on delivery service; this way, customers can see the quality, feel satisfied, and then pay. It is especially useful for customers who might be initially concerned about quality.

Superior Materials

WellPCB uses only materials and parts from certified international websites which offer guaranteed quality. No cheap or inferior product ever comes even close to your PCB. We provide only the best for our customers.

Low Cost and Promotional Offers

For first time customers, we at WellPCB provide special discounted services. For example, for just 1$ you can get 3 PCBs.We also have various promotions at regular intervals and on festive occasions.

Chapter 6: Conclusion

Turnkey PCB fabrication and assembly are all about choosing the right manufacturer and utilizing the latest and most accurate production processes in the industry. WellPCB offers all the above points at remarkable pricing and makes sure you get a high-quality product.

For ordering and more information visit: https://www.wellpcb.com