Boron nitride is an advanced ceramic material that we are all familiar with. It has six crystal types, the most common are cubic boron nitride (c-BN) and hexagonal boron nitride (h-BN), also known as white graphite, with excellent thermal conductivity and insulation characteristics, so it is one of the most important crystal types.

With hexagonal crystal boron nitride, according to different products can continue to separate different products, first, using free sintering, thermal sintering, thermal and other high temperature sintering process —— is generally considered that thermal sintering is the ideal sintering, thermal compression method of ceramics has high density, high strength, mature production process and other advantages are widely used, using chemical vapor deposition technology (Pyrolytic Boron Nitride, PBN). What is the difference between the two, we use hot pressure boron nitride and pyrolysis boron nitride to compare.

- Hot pressure of boron nitride

Thermopressed boron nitride is actually a ceramic material prepared by thermopressed sintering technology. Hot pressure boron nitride is an excellent electric insulator, with excellent lubrication and high temperature stability, even at a very high temperature, but also can maintain its lubrication and inertia. Boron nitride is relatively poor in its mechanical properties, but it has a very high thermal capacity, excellent thermal conductivity, outstanding dielectric strength, and easy workability. In an inert atmosphere, boron nitride can withstand high temperatures over 2000℃ and therefore is therefore an ideal high temperature thermal insulation.

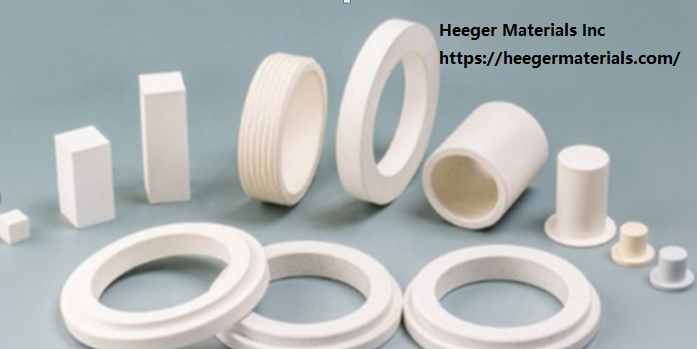

In addition, the hot pressure boron nitride has the characteristics of anisotropy, when the atoms are arranged in the pressure direction perpendicular to the strong bond, showing excellent strength, thermal and electrical properties. Weak bonds are formed when the atoms are arranged parallel to the pressure direction, showing excellent lubricity. According to the above characteristics, using the excellent chemical stability of boron nitride ceramics, it can be used as a crucible, boat plate, liquid metal conveying pipe, crucible for synthetic GaAs crystal, rocket nozzle, high-power device base, molten metal pipe, pump parts, cast steel mold, insulating materials, etc.

- Thermopyrolysis of boron nitride

Therrolysis of boron nitride is the use of chemical vapor deposition technology, at high temperature, by ammonia and boron halide under high vacuum chemical vapor deposition (CVD), can be deposited into PBN sheet material, can be directly deposited into pipe, ring or thin-walled containers and other PBN final products.

This kind of boron nitride prepared by high temperature pyrolysis reaction has high purity, high thermal conductivity, high mechanical strength, good electrical insulation and non-toxic specific energy, chemical inert, and excellent structure and performance, which makes it an ideal container for element purification and the growth of compounds and compound semiconductor crystals. The main applications are OLED evaporation unit, semiconductor single crystal growth (VGF, LEC) crucible, molecular beam epitaxy (MBE) evaporation crucible, MOCVD heater, polycrystalline synthesis boat, high temperature, high vacuum equipment insulation board, etc.

The main characteristic of pyrolysis of boron nitride is a very high purity, up to 99.999% (hot pressure of boron nitride is usually only about 99% purity), its preparation process without the addition of any sintering agent. Therefore, the pyrolysis of boron nitride has many unique characteristics, such as excellent chemical stability and thermal stability, no pore, good density (its density is close to the theoretical density value of the material) and so on.

But one drawback of PBN versus hot pressure B nitride is cheaper (because deposition is slow), so PBN products are more expensive.