Not only can CNC machining assist those looking to create a single prototype or large-scale productions, but it can also help to reduce manufacturing costs as well, which is usually the main priority.

The decisions you make while designing are what determines your final cost. Therefore, to lower your overall price, you can optimize the manufacture parts in compliance with your design requirements.

With CNC machining and the associated CNC machining services, the first thing we examine is what drives pricing. Then, we provide you with a comprehensive, actionable guidelines list proven to lower the cost of CNC machined parts.

What affects the Price of CNC parts?

The following are the factors that affect the cost of CNC machined parts:

Machining time

Machining time is usually the main cost factor in CNC as the longer machining a part takes, the more it will cost.

Start-up costs

The fixed cost of the unit price can be reduced by utilizing “economies of scale”. These are related to process planning and CAD file preparation, which are substantial for lesser volumes.

Material cost

The overall cost can be reduced substantially by optimizing your design using certain materials that are easier to be machined in CNC.

Other Manufacturing costs

Designing parts with special conditions, such as thin walls or tight tolerances, may require closer quality control, special tooling, or other steps that use lower machining speeds which takes more manufacturing time, and impacts price.

Now that you know the key factors in determining the overall cost to get a free CNC machining quote.

Here are some tips to reduce your price:

Tip #1 – Add a Radius in Internal Vertical Edges

Tip #2 – Limit the Depth of Cavities

Tip #3 – Increase Thickness of Thin Walls

Tip #4 – Limit the Length of Threads

Tip #5 – Design Standard Sized Holes

Tip #6 – Only Specify Tolerances when Necessary

Tip #7 – Keep Machine Setups to a Minimum

Tip #8 – Avoid Small Features, that have High Aspect Ratio

Tip #9 – Remove all Lettering & Text

Tip #10 – Contemplate the Machinability of the Material

Tip #11 – Consider the Cost of Bulk Material

Tip #12 – Avoid Multiple Surface Finishes

Tip #13 – Think Blank Size

Extra Tip: Utilize Economies of Scale

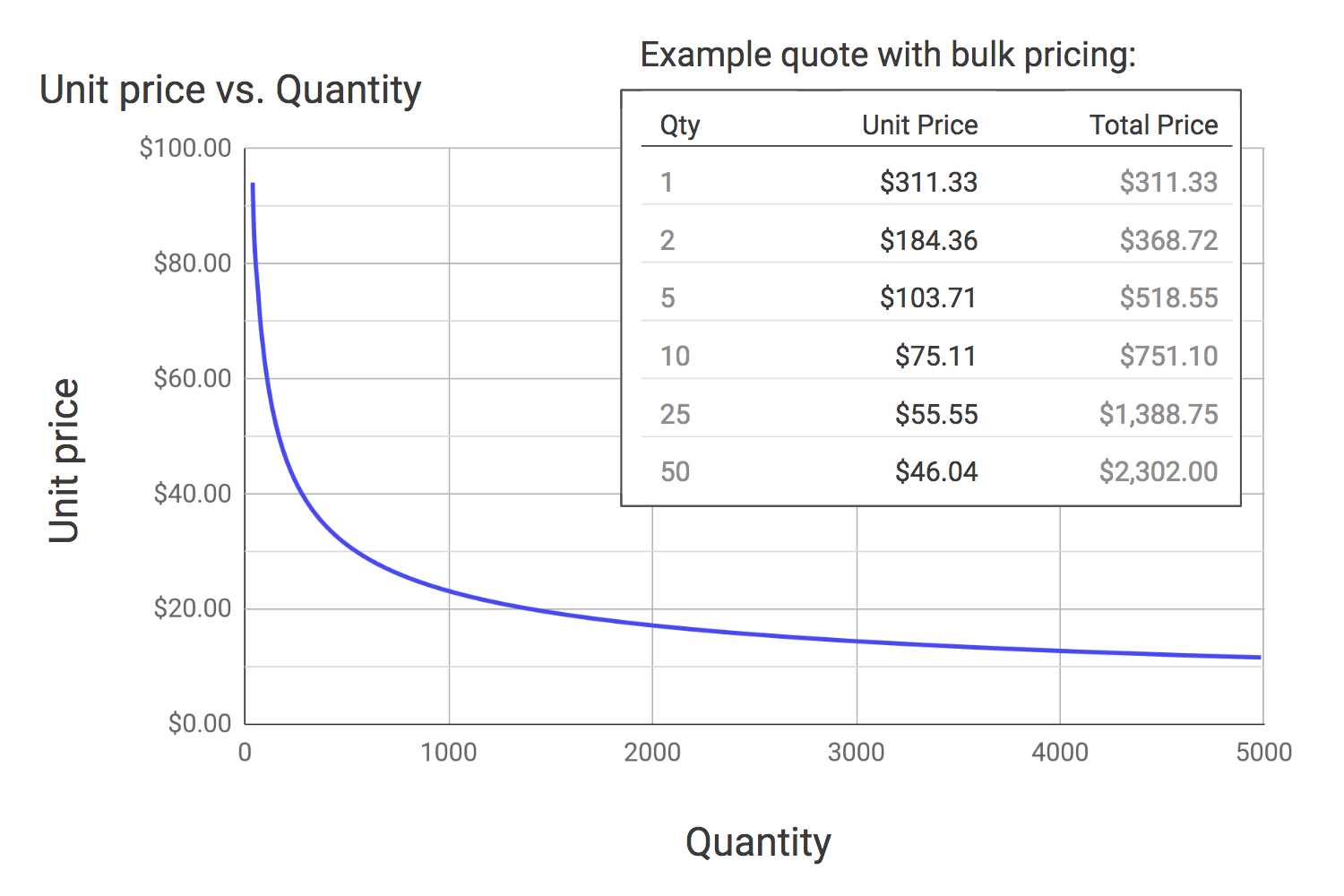

The quantity affects the unit price substantially in CNC services as startup costs are moderately high and low quantities represent a high percentage of the price. However, large quantities are almost eliminated since the costs are spread out over many parts.

In conclusion

Try to keep things standard with CNC services, complexity costs more: geometries that require fixtures, special tooling, specialty materials, or multiple machine setups will be priced higher.

To keep the cost down to a minimum, answer the following questions before submitting an order for a quote:

- Did I use the Designing for Machinability guidelines to optimize my part?

- Can I split my design into multiple parts and then assemble it to make it easier on the CNC machine?

- Are all the features included in my model necessary? Can I simplify or remove any of them while still retaining the full functionality of my part?

- Is there a cheaper or easier machine, material that can meet my design requirements?

- Can my design be modified to eliminate special tooling or multiple machine setups?